Energy efficiency projects

Sustainability

Energy efficiency projects

A number of projects are currently being carried out at DESY to increase its energy efficiency. At the moment, these are mainly focused on the heat supply. This includes extracting waste heat in the cryogenic plant and possibilities for extracting waste heat when cooling the accelerators.

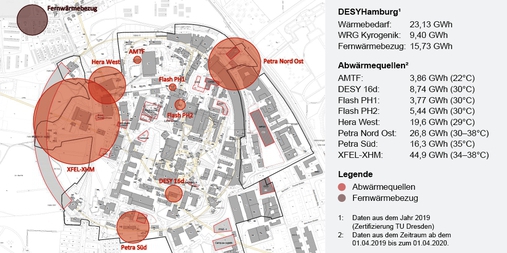

First results of the potential analysis of waste heat: The usable waste heat quantities strongly exceed the current heat consumption at DESY.

Waste heat recovery in the cryogenic plant

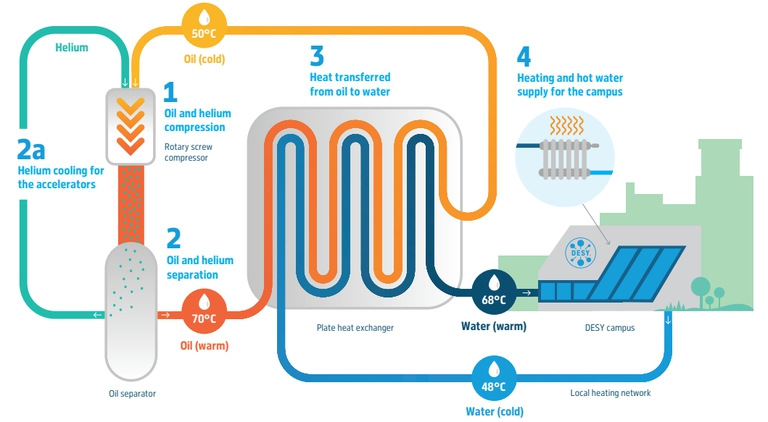

Waste heat is used at DESY in the field of cryogenics, i.e. the low-temperature refrigeration system. Here, helium is cooled down to -271°C (2 Kelvin) and liquefied to create superconducting conditions for the electrons in the accelerators. Part of the current waste heat recovery system was already installed back in the early 1990s, when the facility was built. Waste heat is generated when the helium is compressed. Heat exchangers transfer the waste heat from the oil circuits of the low-pressure compressors in the cryogenic system to the low-pressure side of the heating network. Since the plant was built, the waste heat fed into the heating network has been used to supply a number of buildings on campus.

Heat can also be extracted from the high-pressure stage of the cryogenic plant, and used to heat the DESY site. The waste heat from this process reaches temperatures of almost 70°C and is perfect for supplying heat to the existing buildings on campus. It is also fed into DESY’s local heating network via heat exchangers and thus transported all around the site. The waste heat recovered in this way covers about a third of DESY’s heating requirements. The heat exchanger installed in the high-pressure stage of the cryogenic plant has been in operation since mid-2017.

A detailed article on the recovery of waste heat in the cryogenic plant since 2017 can be found here in the Sustainability Report on page 6-8.

Waste heat extraction from the accelerator cooling system

Another opportunity for recovering waste heat is the cooling water from the accelerators. These systems are cooled using cold water at 20°C. The cooling water heats up to about 30–32°C in the process and then has to be cooled back down to 20°C. At present, the waste heat generated is released into the environment unused, via cooling towers.

Traditional radiators in the existing buildings operate with a flow temperature of around 70°C. Due to their small surface area they are not suitable for a 30°C supply. However, the low temperature can be compensated by a larger heating surface. For surface heating, such as underfloor heating, water at a temperature of 30°C is sufficient as a heat source. DESY is currently planning to equip all future new buildings with surface heating systems, so that they can utilise the waste heat at 30°C. If all sources of waste heat were used, it would even be possible to supply heat to some neighbourhood areas.